Description of services

Paraglider check

1. Confirmation email at

Package entry

You will be informed as soon as your package has arrived here

2. Porosity measurement

The air permeability of the cloth is tested according to the manufacturer's specifications

3. Betsometer test

If necessary, the tensile strength of the cloth is checked

4. Inflate and x-ray the umbrella

By inflating, damage to the cloth such as tears, holes, damage to cell walls / diagonal strips can be identified much more easily and reliably.

5. Visual inspection of the cap with all components

In addition to the cloth, loops, sewing edging tapes, etc. are also subjected to a visual inspection here. Taping a few smaller holes is free of charge.

6. Line control

A visual and haptic control of each individual line including sewing

7. Check the shoulder strap

Sewing, belt length, snaps / magnets, trimmers, brake rollers and handles, line locks and line safety devices are checked here

8. Line strength

According to the manufacturer's specifications, lines are removed if necessary and subjected to a tear test. For this purpose, new lines are manufactured and installed. Up to three lines to be torn are included in the price.

9. Survey

When measuring, each line including the brake lines is measured with a laser and recorded in the program.

10. Line trim

The glider is brought as close as possible to the optimal trim condition.

11. Re-measuring

Unless the manufacturer specifies otherwise, the changed lines will be measured again after the trim and, if necessary, trimmed again.

12. Attaching the verification confirmation to the screen

It is noted here when the screen must be presented for the next test according to the manufacturer's specifications.

13. Checkprotokoll

You get access to the check program and can view the result of the check here and download the check log.

14. Image documentation

In the check program, some pictures of your glider are stored in some test steps. You can download this and use it for your own purposes.

15. Shipping confirmation with parcel tracking

As soon as your equipment has been sent with DHL, you will receive an email with the tracking number.

Rescue pack

1. Triggering and ventilation

The reserve parachute is ventilated for 12 to 24 hours

2. Pack according to the manufacturer's specifications

Here all packing rubbers are renewed

3. Visual inspection of the inner container

For damage, stuck eyelets, release handle, lock, split pins .....

4. Einbau in Gurtzeug / Frontcontainer

On request, we can install the rescue system and carry out a deployment test / functional test.

5. Documentation

The packing is confirmed in the packing slip or online, depending on the manufacturer. In addition, various steps are documented with photos.

Rescue check

1. Hang up

The rescue is spread out and hung flat

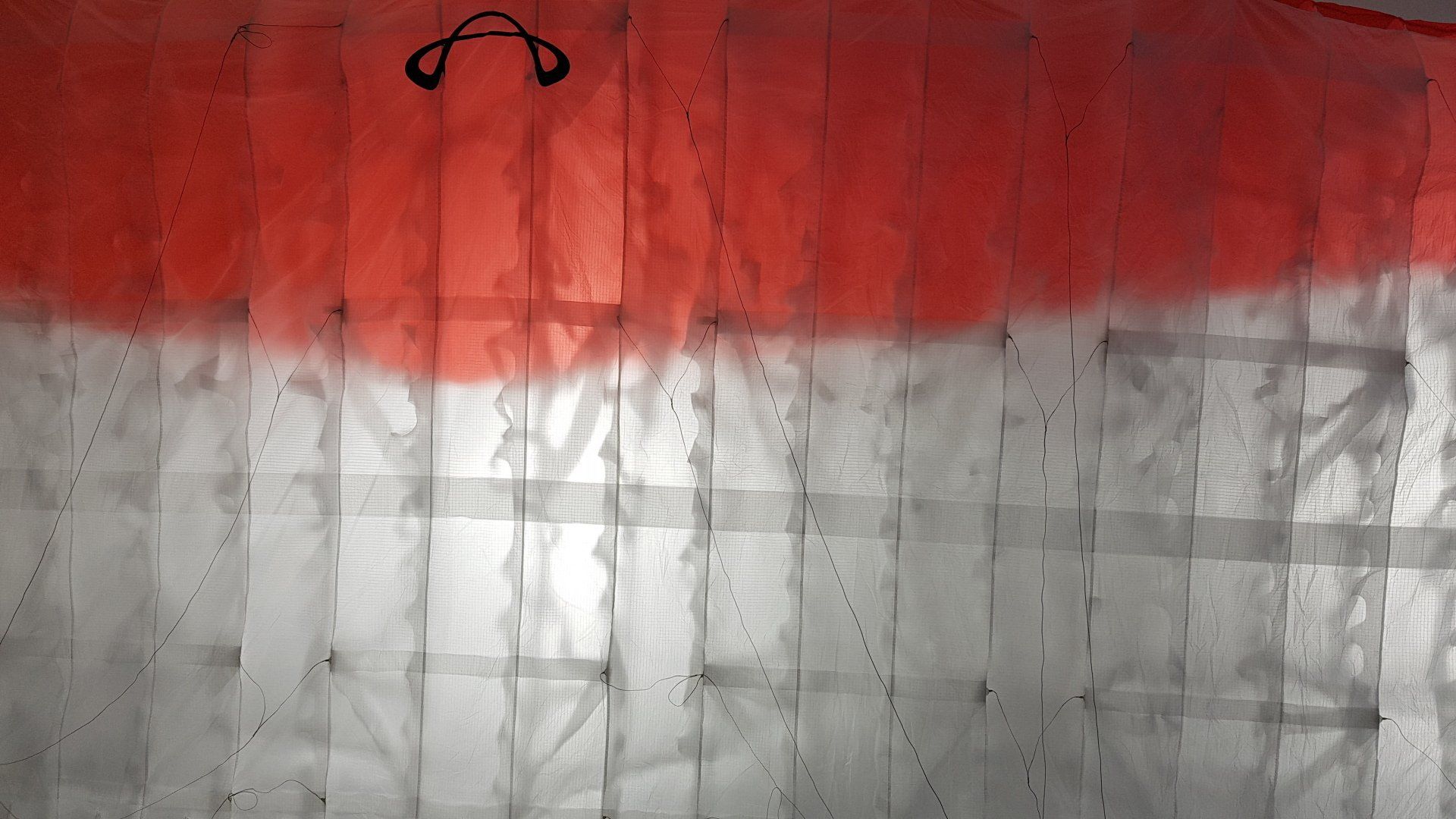

2. X-raying

The cloth is illuminated with powerful spotlights

3. Visual inspection of the cloth

In the light, the cloth is checked for damage, the seams, line attachment points and the packing loops.

4. Visual inspection of the lines

All lines are checked for damage, length and sewing

5. Create a protocol

The review is documented in a protocol.